Paver block manufacturing is an overwhelming job, especially when one handles it manually. That is why choosing the right and high quality paver block maker is highly essential. Though most people focus only on initial price of these machines rather than looking at their required features. One must understand that when investing in paver block maker, performance, durability and its features are what one must look for. Choosing the one that excels in these will help boost productivity and will also help your paver business grow.

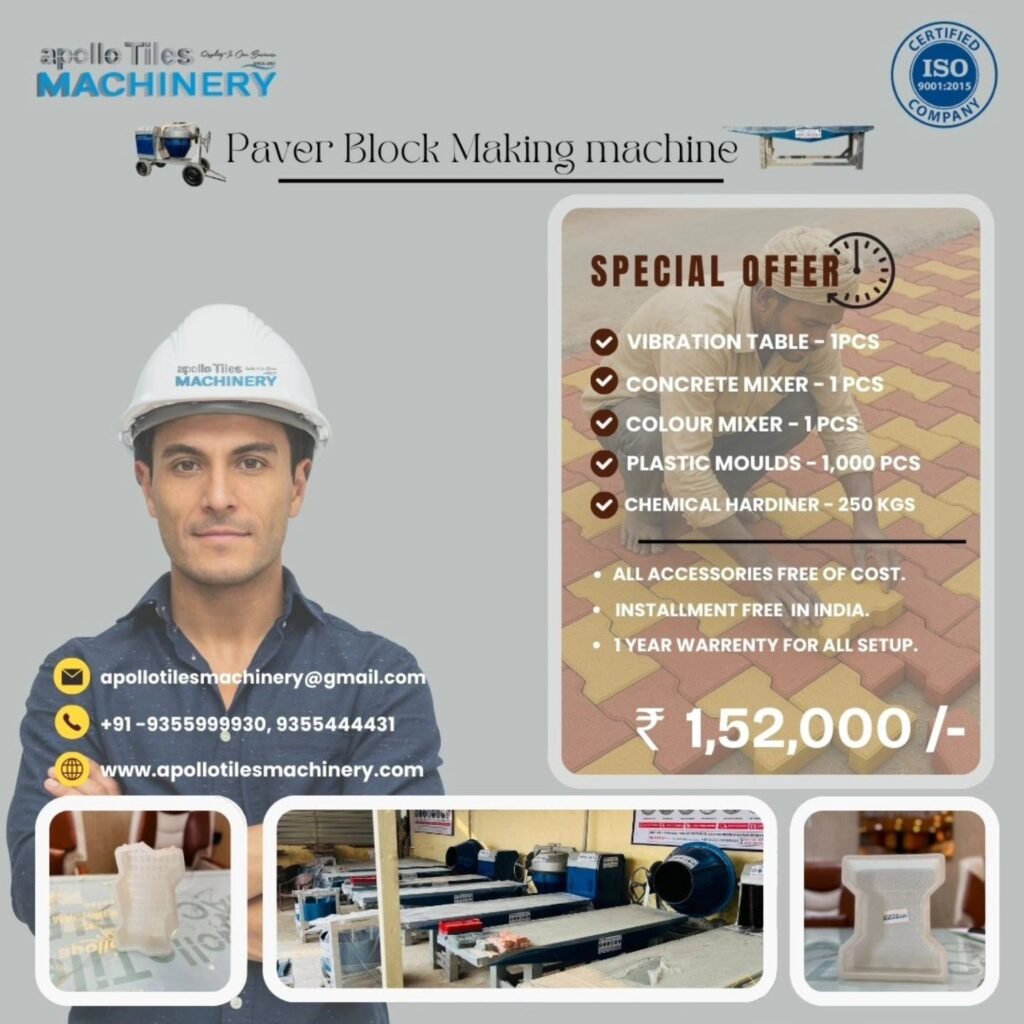

We being one of the reliable paver block maker manufacturers are here to make people aware of a few common mistakes that one makes when buying these machines. As a trusted brand, we always keep our customers informed, so that they can avoid these mistakes and buy premium quality paver block manufacturing machines.

Buying wrong model of paver block maker

Paver block business requirement may vary from business to business. While some may require a machine that produces high quality but large number of paver block. Whereas a few businesses may require a machine that can produce paver blocks of different sizes and using different material. Being unaware of the same, buyers often choose wrong paver block maker which does not match their business requirements. It only ends up making them loose money on buying wrong machine. It is advised to check your requirements first and share the same with manufacturer to find high quality paver block maker.

Not checking the quality of molds and accessories

The paver block machine may be of high quality, but when buying it, there are several other factors to consider. Buyers often ignore the quality of molds and accessories and that is what results into poor production. If the molds are not of good quality, the final output suffers making one bear huge loss. Molds directly influence the finish, strength and accuracy of paver blocks. Poor molds cause uneven shapes or weak edges, affecting the quality of paver blocks. We always advise buyers to check the durability, precision and finishing of the molds before completing the purchase.

Considering low cost over other factors

When investing in paver block makers, selecting the ones that are cheaper can lead to disappointment. One must understand that you might save initial cost on the investment, but when it comes to production, your business will fail. Eventually, it will lead to loss of resources and money both. That is why, one must look for other factors rather than only considering the price. When buying high quality paver block maker, one must ensure build quality, production capacity, and maintenance requirement. Also, check whether the paver block machine is quality tested or not.

Conclusion

Making a smart investment requires a clear understanding of both technical and practical needs. When you avoid these common mistakes and focus on long term performance, you ensure stronger returns and stable productivity. A high quality paver block maker becomes more than an equipment when you avoid these mistakes and focus on its quality and features when buying it. We at Apollo Tiles & Machinery, are known for offering quality tested and premium paver block machines that will help your business flourish.